Tofu Liquid Waste Treatment Using Anaerob-aerobic Biofilm Aeration System to Reduce BOD COD and Ammoniac Content

Download

Abstract

Background: Tofu derived from processed soybeans is popular with the public, but tofu production has an unfavourable effect. After all, it produces liquid waste that causes quite high pollution because it contains quite high organic components. The study aimed to reduce the content of Biochemical Oxygen Demand (BOD), Chemical Oxygen Demand (COD), and Ammonia in the liquid waste of a tofu factory. The scope of this research is limited to reducing the content of BOD, COD, and NH3 (Ammonia) with an anaerobic-aerobic biofilm aeration system.

Materials and Methods: This research was conducted at the Sanitation Study Program Campus, health polytechnic, Ministry of Health, Jambi from March to August 2020. Sample examination was carried out at the Regional Health Laboratory of Jambi Province. This is an experimental study with a pre-post test only design and one group post-test design. The population in this study is the tofu industry, and the sample in this study is partly water from tofu waste.

Results: The results showed a decrease in BOD, COD and Ammonia after passing through a tofu waste treatment machine using anaerobic and aerobic biofilms with BOD values of 64.6%, COD of 49.6% and Ammonia of 79.8%. The statistical test results showed that the p-value was 0.0001 for the decrease in BOD, the p-value was 0.0001 for COD, and the p-value for ammonia was 0.0001. A significant decrease in DOD, COD and Ammonia after passing through the waste treatment equipment with Anaerobic and Aerobic Biophiles.

Conclusion: This tool can be used by adding several parts and treatments such as filtering, settling basins, and adding other chemical substances. On the surface of the bio ball used, it was found that the growth of biofilm was found and to increase the ability of the equipment, initial treatment was needed, such as filtration and sedimentation of waste, reducing acidity with the help of quicklime.

Introduction

Tofu is a processed soybean product that is quite popular with the public [1,2]. In the manufacturing process, the tofu industry produces much liquid waste that causes quite high pollution because it contains organic components that can harm the environment [3], [4]. Tofu liquid waste has a Chemical Oxygen Demand (COD) concentration ranging from 10,000 to 20,000 ppm, caused by the protein content found in liquid tofu waste. Liquid waste with a high COD value can cause the death of aquatic biota if directly discharged into the waters. Fish are usually used as an indicator of pollution in waters because they have a quick response to environmental disturbances [5]. Tofu liquid waste treated aerobically requires a large cost in its production [6,7]. The treatment of wastewater with a high COD value is generally carried out an aerobically because it can be operated easily, the operating costs are low, and the WWTP design is simple [8-10].

In the manufacture of tofu, the resulting waste contains high protein, organic matter and dissolved solids, with a low pH. In addition, it will also cause an unpleasant aroma that interferes with the aesthetics and life of the surrounding ecosystem [11, 12].

Generally, tofu production ranges from 1,200 kg to 1,500,000 kg per year, while the amount of liquid waste produced reaches approximately 2 m3 for every one quintal of soybeans [13]. Thus, the pollution load from the tofu industry is quite large, so it requires further handling to comply with the quality standards. Wastewater parameters that stand out from tofu waste are temperature, pH, suspended solids, dissolved solids, and Biochemical Oxygen Demand (BOD) [3, 5, 14].

Biochemical Oxygen Demand (BOD) measures the oxygen demand in wastewater or the oxygen required by microorganisms to oxidize chemical compounds [15], [16]. The oxidation process is very slow and theoretically takes infinite time. The BOD value is useful to determine whether the wastewater is biodegraded or not. The BOD parameter, in general, is widely used to determine the level of wastewater pollution [5, 17]. Determination of BOD is very important to trace the flow of pollution from upstream. The determination of BOD is a bioassay procedure involving the measurement of the amount of oxygen used by organisms as long as these organisms decompose organic matter present in water, under conditions almost the same as those in nature. During the BOD inspection, the sample being examined must be free from the outside air to prevent contamination from oxygen in the free air. The concentration of the wastewater (sample) must also be at a certain level of pollution to keep dissolved oxygen always present during the inspection. It is important to note, considering that the solubility of oxygen in water is limited and only around ± 9 ppm at a temperature of 27°C [3, 5].

Tofu-making industrial waste is generally directly discharged into waterways, resulting in pollution of the waters [12]. Polluted waters have a high BOD content, low pH, have a foul smell and are black, so they cannot be used anymore. Liquid waste or tofu wastewater is disposed of and generally contains materials or substances that can harm human health and disturb the environment.

This study aims to treat tofu liquid waste with an anaerobic-aerobic biofilm aeration system in reducing the content of BOD, COD and ammonia.

Materials and Methods

The research design used a quantitative research design with an experimental approach. Experimental research is a study that seeks to find the effect of certain variables on other variables under tightly controlled conditions. Experimental research is a systematic method for building relationships that contain causal phenomena.

The population in this study was the tofu industry, and the sample in this study was part of the water from tofu waste, totaling 36 samples consisting of samples for examination of 2 BOD before and after treatment with six repetitions so that it became 12, 2 samples of COD before and after treatment with six repetitions so that it became 12, sample 2 Ammonia before and after with six repetitions so that it becomes 12. Each parameter consists of 12 samples, meaning that the total sample is 36.

Data were collected by conducting a preliminary survey of the tofu industry in Jambi city, then conducting interviews using a questionnaire, taking samples of tofu waste, and checking the content of BOD, COD, and Ammonia.

Making modifications of tofu waste treatment equipment using anaerobic and aerobic biofilms. This tool is made as simple as possible with the materials and equipment around, especially the widely used drums in the market. Some materials must be ordered outside the city because there is no production here like Bio ball. The tools were made in the workshop of the Environmental Health Department, Poltekkes, Ministry of Health, Jambi. Several students assist the making the tofu. It is also a medium of learning for them. The working procedure is as follows:

1. Preparation of tools and materials to be used.

2. Clean the used drums that have been purchased. Drums are usually cleaned of chemicals, but re-washing is done using soap and pressurized water (Water-jet).

3. The clean and dry drum begins to be measured to make a pattern for the part to be cut and make holes.

4. Cutting the top of the drum for the path of stringing the pipe in the drum.

5. Make holes in several parts of the drum using a drilling machine with a diameter of 4 inches.

6. Cut the PVC 4 inch pipe to the required length.

7. Trying to install a series of pipes and drums without glueing them first.

8. Making baskets for bio ball

9. Prepare the blower and water pump at the top of the drum

10. Arrange electrical circuits as a source of energy for blowers and water pumps

11. Putting the series of tools in place provided for the series of tools are permanently installed and glued together with glue and coated with aquarium glue, so they do not leak.

12. Taking tofu waste and filling it into the tool.

13. The equipment is operated to grow bio films an aerobically and aerobically for ten days.

14. After ten days, the tool is ready for use, marked by the appearance of a bio film on the bio ball in the tool.

15. Sampling before entering the tofu waste treatment equipment and after processing the tofu waste.

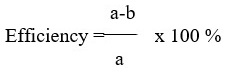

16. The sample was repeated and immediately brought to the BLDH environmental laboratory in Jambi province. Data analysis was carried out after knowing the test data for each BOD, COD, and Ammonia parameter before and after processing. Data analysis also aims to determine the effect of the anaerobic-aerobic treatment system on decreasing the parameters of BOD, COD, and Ammonia and processing efficiency, which is affected by the hydraulic residence time treatment and to determine the optimal hydraulic residence time. Determination of the efficiency of BOD, COD, and Ammonia levels was calculated to determine how much the level of reduction in BOD, COD, and Ammonia levels was before and after the combined anaerobic-aerobic system processing was carried out. The calculation to obtain the efficiency value is as follows:

a: BOD, COD, and ammonia concentration values before being processed for each treatment

b: BOD, COD, and ammonia concentration values after processing for each treatment

In addition, the test results data on the parameters are processed for analysis using the t-test, with the assessment criteria if the p-value 0.05, then there is a significant difference in the decrease in concentration before and after passing the tofu waste treatment tool using the SPSS version 16.0 application.

Results

The results of the study began with the construction of an anaerobic and aerobic tofu waste treatment plant with the following figure (Figure 1 and 2):

Figure 1. Blower and Water Pump.

Figure 2. Use of Bioball.

In this study, the working steps of the operation of the tofu waste treatment using anaerobic and aerobic biofilms are as follows:

1. The tool is in a ready-to-use condition

2. Extraction of tofu waste for biofilm formation

3. Put all tofu waste into the tofu waste treatment equipment using anaerobic and aerobic biofilms 4. Turn on the blower aerator and water pump

5. Allow the tool to operate for ten days until a biofilm is formed on the bio ball in the tool

6. Checked every day

7. The remaining tofu waste from biofilm breeding is disposed of and filled with new tofu waste

8. Measure the temperature and acidity of the tofu waste in the first drum

9. Take the tofu waste in the first drum using a 2-litre plastic jerry can and label it as the first sample for BOD, COD and Ammonia inspection before passing through the tofu waste treatment equipment using anaerobic and aerobic biofilms

10. Let the tofu waste flow until it reaches the fifth drum.

11. Check the temperature and acidity at the fifth drum outlet

12. Take the tofu waste from the fifth drum outlet using a 2-litre plastic jerry can and label it as the second sample for BOD, COD and Ammonia examination after passing through the tofu waste treatment equipment anaerobic and aerobic biofilm, repeated six times.

Table 1 shows the average temperature data before processing using tofu waste processing equipment using anaerobic and aerobic biofilms is 36.16oC, and the average temperature after processing tofu waste is 32 oC. Anaerobic and aerobic biofilms were pH 3.8, and the average pH after tofu waste treatment was 6.25.

| Repetition | Temperature oC | pH | ||

| Before | After | Before | After | |

| First | 36 | 30 | 3 | 6,5 |

| Second | 37 | 30 | 4 | 6 |

| Third | 37 | 34 | 4 | 6 |

| Fourth | 36 | 34 | 5 | 6,5 |

| Fifth | 35 | 30 | 3 | 5,5 |

| Sixth | 36 | 34 | 4 | 7 |

| Average | 36,16 | 32 | 3,8 | 6,25 |

Table 2 shows the average BOD data before processing using tofu waste treatment using anaerobic and aerobic bio films is 616 mg/l, and the average BOD after tofu waste treatment is 218 mg/l with an average decrease of 63.5%.

| Measurement Time | BOD Concentration (Standard 150 mg/l) | Effectivity (%) | |

| Before (mg/l) | After (mg/l) | ||

| 1 | 700 | 250 | 60 |

| 2 | 650 | 200 | 66,6 |

| 3 | 690 | 180 | 78,5 |

| 4 | 600 | 200 | 66,6 |

| 5 | 560 | 250 | 55,3 |

| 6 | 500 | 230 | 54 |

| Average | 616 | 218 | 63,5 |

| Sig. | 0,0001 |

Table 3 shows the average COD before processing using tofu waste treatment using anaerobic and aerobic biofilms was 1,124 mg/l, and the average COD after tofu processing was 566 mg/l with an average percentage decrease of 54.3%.

| Measurement Time | BOD Concentration (Standard 300 mg/l) | Effectivity (%) | |

| Before (mg/l) | After (mg/l) | ||

| 1 | 1.600 | 750 | 53,1 |

| 2 | 1.500 | 600 | 60 |

| 3 | 980 | 550 | 43,8 |

| 4 | 1.300 | 600 | 53,8 |

| 5 | 1.200 | 560 | 53,3 |

| 6 | 900 | 340 | 62,2 |

| Average | 1.124 | 566 | 54,3 |

| Sig. | 0,0001 |

Table 4 shows the average Ammonia before processing using tofu waste treatment equipment shows a value of 0.76 mg/l, while after filtering using anaerobic and aerobic biofilms, the ammonia concentration decreases to 0.16 mg/l.

| Measurement Time | Ammonia Concentration (Standard 0,1mg/l) | Effectivity (%) | |

| Before (mg/l) | After (mg/l) | ||

| 1 | 0,76 | 0,12 | 84,2 |

| 2 | 0,65 | 0,28 | 56,9 |

| 3 | 0,88 | 0,18 | 79,5 |

| 4 | 0,63 | 0,14 | 77,7 |

| 5 | 0,77 | 0,10 | 87 |

| 6 | 0,91 | 0,19 | 79,1 |

| Average | 0,76 | 0,16 | 77,4 |

| Sig. | 0,0001 |

Discussion

Based on the research results, the BOD present in tofu waste has a high concentration and exceeds the quality standard of liquid waste that has been set by the government, which is 150 mg/l. The presence of high BOD cannot be separated from the amount of protein and other organic substances present in tofu waste. Based on the results of the UI statistic, it is known that the p-value of 0.027 means that there is a significant decrease in the concentration of BOD in tofu waste after passing through the tofu waste treatment equipment with inorganic and organic biofilms.

Organic materials contained in tofu industrial effluents are generally very high. Organic compounds in the wastewater can be proteins, carbohydrates, fats and oils [18]. Among these compounds, protein and fat are the largest, reaching 40% - 60% protein, 25 - 50% carbohydrates, and 10% fat. One indicator to assess the content of organic matter is to test the concentration of BOD in water. The high content of BOD in water will make it difficult for the decomposition carried out by natural microorganisms present in tofu waste. BOD concentration is one of the key parameters in wastewater, meaning that its presence and amount in wastewater will affect the concentration of other pollutants, especially organic waste such as tofu waste [19, 20].

The average BOD concentration before treatment with tofu waste treatment equipment using anaerobic and aerobic biofilms has been able to reduce the average BOD from 616 mg/l to 218 mg/l with an average decrease of 64.6%. Still above 150 mg/l under the wastewater quality standard. It is a parameter to assess the amount of dissolved organic matter and shows the amount of oxygen required by the activity of microorganisms in decomposing organic substances biologically in the liquid waste. The liquid waste of the tofu industry contains high dissolved organic materials.

According to Sayow [21], BOD is the number of oxygen organisms needed to break down organic waste in the waters. The higher the BOD concentration, the more oxygen is needed to oxidize organic matter.

A high BOD value indicates many organic compounds in the waste, so microorganisms need that much oxygen to decompose organic compounds. A low BOD value indicates the decomposition of organic waste by microorganisms [22].

The average Chemical Oxygen Demand (COD) before processing using tofu waste treatment using anaerobic and aerobic bio films was 1.124 mg/l, and the average Chemical Oxygen Demand (COD) after tofu waste treatment was 566 mg/l, with an average percentage decrease of 49.6%. It shows that the bacteria that grow in the drum reactor with PVC pipe bio filter media effectively reduce COD levels of tofu waste and are effective up to 62.2%.

The initial high concentration of tofu waste occurred due to the adaptation process of microorganisms that grew and reproduced in the fishnet bio filter media and bio ball in the drum (bio filter reactor) to the new tofu liquid waste. High COD values occur because of environmental factors that influence such as the dissolved oxygen content in the reactor is sufficient to help bacteria decompose pollutant compounds in the reactor. Furthermore, tofu contains high protein, so liquid tofu waste will also contain high organic materials. It proves that the concentration of pollutants in tofu waste is still high.

Currently, the management of tofu and fermented soybean industrial wastewater is generally carried out by making a wastewater reservoir so that an anaerobic process occurs. With the anaerobic biological process, the organic pollutant content in the wastewater can be reduced, but with this process, the treatment efficiency is only around 50% - 70%. Thus, if the COD concentration in wastewater is 7000 ppm, then the level of COD that comes out is still quite high, around 2100 ppm, so this is still a source of environmental pollution [23-25].

The value of ammonia concentration before using anaerobic and aerobic biofilms was 0.76 mg/l and then decreased after tofu waste treatment to 0.16 mg/l with an average efficiency reduction of 77.4%. In general, the tofu industry only accommodates waste in one tub or even earthen ponds and some even discharge directly into public channels or rivers without any storage or treatment. In line with the increase in the operational time of the biofilter reactor, it appears that the effectiveness of the ammonia content has increased. The micro-organisms in the biofilter reactor have grown and reproduced and formed a thicker biofilm layer than before so that the organic compounds in the liquid waste can be decomposed. In conclusion, after going through a waste treatment device using anaerobic and aerobic biofilms, the liquid waste of the tofu factory showed a decrease in the content of BOD, COD and ammonia, so that the tool can function treat the liquid waste of the tofu factory using anaerobic and aerobic biofilms.

Funding

This research did not receive any grant from funding agencies in the public, commercial, or non-profit sectors.

Authors’ contributions

All authors equally contributed to preparing this article.

Conflict of interest

The authors declared no conflict of interests

References

- Treatment and Utilization of Industrial Tofu Waste in Indonesia Faisal M, Gani A, Mulana F, Daimon H. Asian Journal of Chemistry.2016;28. CrossRef

- “Improving the quality of tofu liquid waste by the sedimentation process and the phytoremediation of water hyacinth (Eichornia crassipes),”. in International Conference on Science and Technology H. Fitrihidajati , F. Rachmadiarti , D. S. Vidyawati . 2018.

- “Decreasing COD and TSS levels of tofu liquid waste using Kangkungan (Ipomeacracicaulis) with phytoremediation method.” D. Widyastuti , D. Suprayitno . .

- Application of Vertical Stainless-Steel Type of Steam Boiler for Home Industry of Tofu Bairawa B, Putra R, Triwitono P. IOP Conference Series: Earth and Environmental Science.2021;757:012068. CrossRef

- Pullulan production from agro-industrial waste and its applications in food industry: A review Singh RS , Kaur N, Kennedy JF . Carbohydrate Polymers.2019;217. CrossRef

- Response Surface Method Application in Tofu Production Liquid Waste Treatment Effndi H, Seroja R, Hariyadi S. Indonesian Journal of Chemistry.2019;19:298. CrossRef

- Tofu wastewater treatment using vetiver grass (Vetiveria zizanioides) and zeliac Seroja R, Effendi H, Hariyadi S. Applied Water Science.2018;8(1):2. CrossRef

- Brewery and Winery Wastewater Treatment: Some Focal Points of Design and Operation. Utilization of By-Products and Treatment of Waste in the Food Industry Brito AG , Peixoto J, Oliveira JM , Oliveira JA , Costa C, Nogueira R, Rodrigues A. Boston, MA.2007;:109-131. CrossRef

- Energy audit in small wastewater treatment plants: methodology, energy consumption indicators, and lessons learned Foladori P, Vaccari M, Vitali F. Water Science and Technology. 2015 06 16;72(6):1007-1015. https://doi. org/.2015;72(6):1007-1015. CrossRef

- The sharon process: An innovative method for nitrogen removal from ammonium-rich waste water Hellinga C, Schellen AAJC , Mulder JW , Loosdrecht MCM , Heijnen JJ . Water Science and Technology.1998;37(9):135-142. CrossRef

- Enhanced volatile fatty acids production from waste activated sludge anaerobic fermentation by adding tofu residue Huang X, Zhao J, Xu Q, Li X, Wang D, Yang Q, Liu Y, Tao Z. Bioresource Technology.2019;274:430-438. CrossRef

- “Water Quality Parameters of Tofu Wastewater: A Review,” in IOP Conference Series: Materials Science and Engineering P. G. L. Putro , H. Hadiyanto . 2021;1156(1):12018.

- Potential Renewable Energy from Tofu Processing Waste in Banda Aceh City, Indonesia Faisal M, Mulana F, Daimon H, Machdar I. Asian Journal of Chemistry.2014;26:6601. CrossRef

- Combination of filter media to reduce total suspended solids, biochemical and chemical oxygen demand in wastewater using installation of horizontal roughing filter Gunam I, Natalia F, Arnata I, Putnarubun C, Setiyo Y, Anggreni A, Mulyani S. Asian Jr. of Microbiol. Biotech. Env. Sc.2016;18.

- Cultivation of Microalgae Chlorella sp on Fresh Water and Waste Water of Tofu Industry Philia J, Wibisono J. 2018;31:04009. CrossRef

- Effectiveness of ozonation process on treating tofu industrial liquid waste: Postgraduate Symposium on Industrial Science and Technology, SISTEC 2019. Sutjipto AGE, Zulkifli FH, Misnon II Wulansarie R, Chafidz A, Hidayat P, Rengga WDP , Afrizal FJ , Dwipawarman A, Bismo S, Arifin R. Industrial Science and Technology.2020. CrossRef

- “The Use of Liquid Waste of Tofu Industry for Biogas Production Using an Anaerobic Digester,” in Seminar Nasional Teknik Kimia Kejuangan S. Soeprijanto , V. A. Tristanto , M. Revandra , E. R. Rohmah , H. E. Febrianto . 2019;:3.

- Utilization of tofu wastewater as a cultivation medium for Chlorella vulgaris and Arthrospira platensis. IOP Conference Series: Earth and Environmental Science Ajijah N, Tjandra B, Hamidah U, Rani W, Sintawardani N. 2020;483:012027. CrossRef

- “Komparasi proses fitoremediasi limbah cair pembuatan tempe menggunakan tiga jenis tanaman air,” E. Novita , A. A. G. Hermawan , S. Wahyuningsih . Jurnal Agroteknologi.2019;13(1):16-24.

- Pengaruh pemakaian biofilter struktur sarang tawon pada pengolah limbah organik sistem kombinasi anaerob-aerob (studi kasus: limbah tahu dan tempe) Herlambang A. Jurnal Teknologi Lingkungan.2001;2(1). CrossRef

- “Analisis Kandungan Limbah Industri Tahu dan Tempe Rahayu di Kelurahan Uner Kecamatan Kawangkoan Kabupaten Minahasa,” Sayow F, Polii BVJ , Tilaar W, Augustine KD . AGRI-SOSIOEKONOMI.2020;16(2):245-252. CrossRef

- “Pengolahan Limbah Cair Pabrik Tahu Dengan Rotating Biological Contactor (Rbc) Pada Skala Laboratorium Menuju Produksi Bersih,” in Prosiding Seminar Nasional Era Industri (SNEI) 4.0 Z. Zulkifli , S. Suhelmi . 2018;1(1):429-36.

- “A Study of the Tofu Industry Environmental Impact Condition and Scenario Treatment Using Life Cycle Assessment Approach,” Rahmalia , S. K. Nisa , V. Palupi , A. Putri , I. W. K. Suryawan . EPI International Journal of Engineering.2021;4(1):7-13. CrossRef

- “An alternative carbon source withdrawn from anaerobic fermentation of soybean wastewater to improve the deep denitrification of tail water,” Z. Xue , et al . Biochemical Engineering Journal.2018;132:217-24. CrossRef

- “Socialization of Tofu Liquid Waste Management (Whey Tofu) Becomes Biogas as Alternative Energy Reserves in the Framework of Creating an Environmentally Friendly Industry,” Kontribusia (Research Dissemination for Community Development) N. A. Mufarida , O. D. Setiawan . 2020;3(2):326-32. CrossRef

License

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

Copyright

© Asian Pacific Journal of Environment and Cancer , 2025

Author Details

How to Cite

- Abstract viewed - 0 times

- PDF (FULL TEXT) downloaded - 0 times

- XML downloaded - 0 times